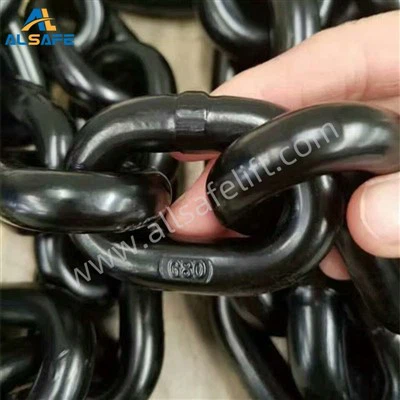

Lifting Equipment

As one of the leading Lifting Equipment suppliers in China, we warmly welcome you to wholesale high-grade Lifting Equipment made in China here from our factory. All our products are with high quality and low price. CD1 MD1 Wire Rope Electric Hoist, Electric Hoist, Ratchet Tie Down Strap