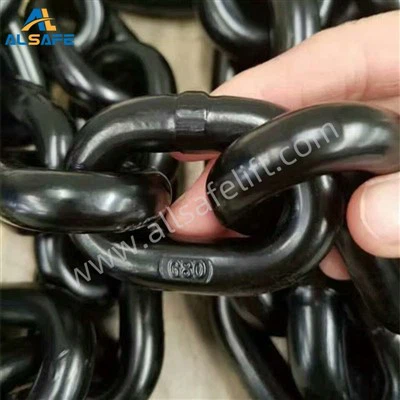

As one of the leading Lever Hoist suppliers in China, we warmly welcome you to wholesale high-grade Lever Hoist made in China here from our factory. All our products are with high quality and low price. Ratchet Lever Hoist, Lever Hoist, Mini Lever Hoist