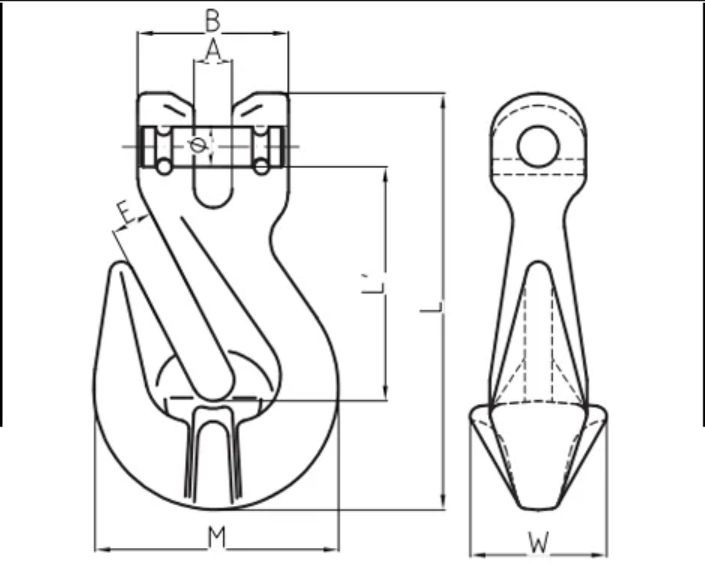

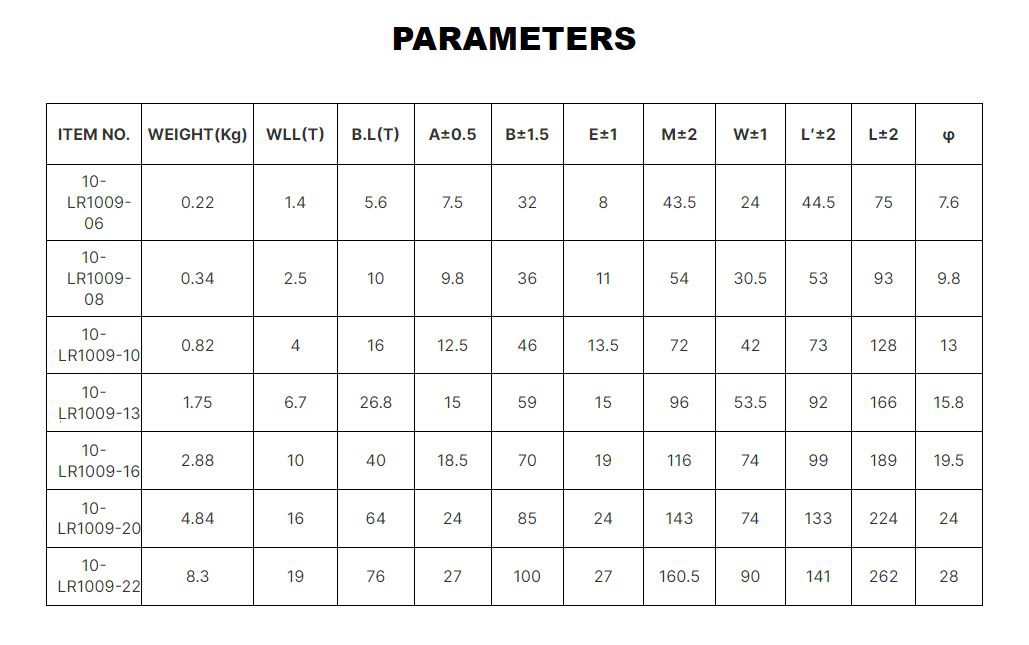

G100 Lifting Hook

Before each use, the operator must perform a safety inspection on the sling and use it only after being qualified;

Send Inquiry

Product Introduction

Features

Precise and safe locking

The locking device is exquisitely designed, the mechanical lock engages tightly, and has excellent anti-detachment performance, eliminating the risk of accidental decoupling and ensuring operational safety.

Ergonomic design

The anti-slip texture fits the palm of the hand, making it effortless and comfortable to control. The appearance is eye-catching and marked with key information such as load-bearing and serial number.

Lightweight and portable

While ensuring strength, it reduces redundant weight and facilitates transportation and installation, which helps improve operating efficiency and is especially suitable for frequent job transfers.

Previous

Eye Safety HookNext

G80 Chain ClutchYou Might Also Like

Send Inquiry