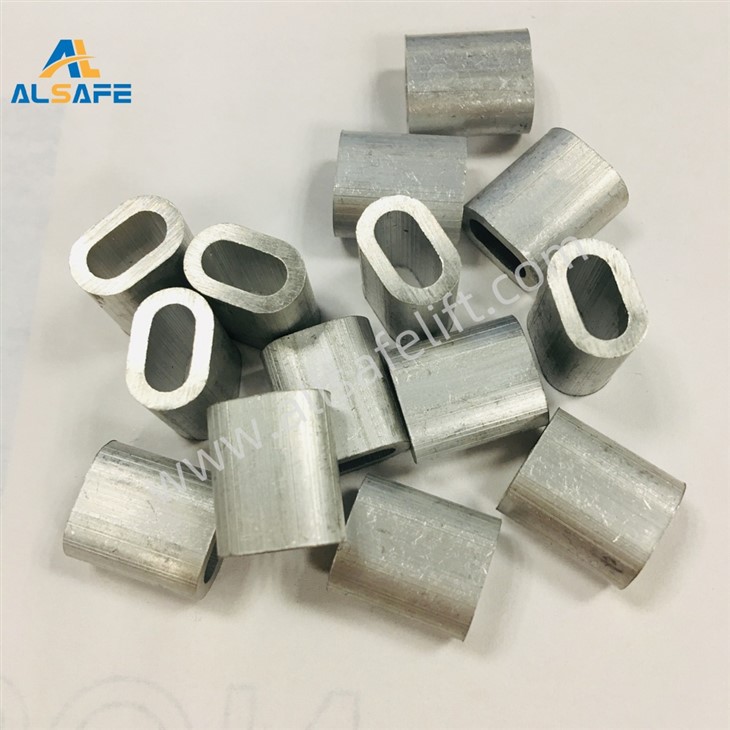

Aluminium Ferrules Sleeves

Professional suppliers are worthy of your trust.

We provide full-service for lifting solutions.

Grade 80 & Grade 100 Materials used for all lifting equipment & riggings.

Overload Automatic Protection Device designed.

CE, GS, TUV & ISO Certified and meet European Quality Requirement.

Prefessional QC team with 20 Years' experience.

high quality

Advanced Equipment

Professiona Team

One-Stop Solution

Premium quality

We have a complete quality control system and conduct strict quality testing and control in every aspect from raw material procurement to production and processing to ensure that our products meet high quality requirements.

Industry experience

Our company has many years of industry experience and can accurately conduct product development and optimization. The professional R&D team explores and improves product performance and quality.

Efficient production

Our production facilities are advanced and efficient, capable of meeting large-scale order demands while ensuring on-time delivery of products, providing customers with reliable supply chain guarantees.

customer service

We provide high-quality customer service and a professional sales team to answer your questions, provide technical support, and can customize personalized product solutions according to your special needs.

Product advantages

Optimized structural design

The structure of the casing is carefully designed to have good sealing and connectivity. Its unique connection method effectively prevents loosening and leakage.

High strength and durability

Made of high-quality aluminum material, Aluminum Ferrules Sleeves have excellent strength and can withstand large pressure and tension without being easily deformed or damaged.

Good corrosion resistance

Aluminum itself has certain corrosion resistance, and our Aluminum Ferrules Sleeves can effectively resist corrosion under harsh environmental conditions and extend the service life of the product.

Broad applicability

It can be used for the connection and protection of wires and cables; for hydraulic pipelines; for brake systems, fuel systems and other pipelines; it has both practicality and aesthetics.

Lightweight characteristics

Aluminum casings are lightweight, easy to transport and install, and have obvious advantages in some application scenarios where weight is required.

High-precision dimensions

Advanced production technology can accurately control the inner diameter, outer diameter, length, etc., ensuring perfect fit with supporting equipment or cables.

Maintenance

Regular cleaning

Use a clean soft cloth or brush to remove dust, dirt and other impurities on the surface to prevent the accumulation of impurities from affecting heat dissipation or causing corrosion. For hard-to-clean stains, use a mild detergent.

Check the connection

Check whether the connection between the sleeve and other components is loose. Check the connection for signs of leakage, identify the cause and repair it, which may require replacing the seal or reinstalling the bushing.

Anti-corrosion treatment

Additional anti-corrosion treatment is required in some special environments. Anti-corrosion paint or anti-corrosion grease can be applied regularly to enhance the corrosion resistance of the casing.

Avoid damage

During installation, use and maintenance, pay attention to avoid mechanical damage. If damage is found on the surface of the casing, minor damage can be repaired; severe damage may require replacement of the casing.

FAQ

Q: How to ensure the quality of Aluminum Ferrules Sleeves?

A: We only use high-quality aluminum material suppliers. Advanced production technology and high-precision processing equipment are used, and each production link has strict quality inspection processes to ensure that the products meet relevant quality standards.

Q: Is it difficult to install Aluminum Ferrules Sleeves?

A: Our product design takes into account the convenience of installation and provides detailed installation guides. Anyone with basic mechanical installation skills can successfully complete the installation as long as they follow the steps in the installation guide. If you encounter problems during the installation process, the technical team provides professional installation guidance services.

Q: Can Aluminum Ferrules Sleeves be custom made to special specifications?

A: Yes. We are able to customize production according to the size, shape, performance requirements, etc. provided by customers. Customers only need to communicate their specific customization needs with our sales team, and we will provide you with personalized product solutions and quotations.

Q: How to contact the after-sales service team?

A: You can contact our service team through the service hotline, email or online customer service platform provided on the company's official website. When contacting, please provide relevant information about the product, such as order number, product model, etc., so that our team can handle your issue more quickly.

More product details

Aluminum wire rope sleeve is a device for connecting and protecting wire ropes, made of aluminum, It is usually a metal sleeve that is put on the end of the wire rope to increase the strength of the connection and prevent the wear of the rope. Aluminum sleeves have light weight and good corrosion resistance, and are often used in hoisting and cable applications.

Model: DIN3093 Aluminium ferrule

The size can make: from 1mm- 56mm

Usage: press wire rope slings

We are manufacturer which make aluminium ferrule more than 20 years. exported more than 100 countries.

Our ferrules are made of strictly material corresponding to the requirements of EN 13411-3(DIN 3093) regarding material composition and mechanical properties.

Hot Tags: Aluminium Ferrules Sleeves, China Aluminium Ferrules Sleeves suppliers, factory, Snatch Block with Hook, Chain Block with Bearing, G80 G100 Master Link and Assembly, Single Sheave Pulley Block, Plain Geared Trolley, VL Type Lever Block

Previous

No InformationNext

G414 ThimbleYou Might Also Like

Send Inquiry